Meet TETRAS.

The asynchronous peptide synthesizer.

This website stores cookies on your computer. These cookies are used to improve your website experience and provide more personalized services to you, both on this website and through other media. To find out more about the cookies we use, see our Privacy Policy.

We won't track your information when you visit our site. But in order to comply with your preferences, we'll have to use just one tiny cookie so that you're not asked to make this choice again.

Meet TETRAS.

The asynchronous peptide synthesizer.

Originally conceived in the mid-2000s, the TETRAS peptide synthesizer was designed to streamline solid-phase peptide synthesis through a smarter, more efficient design.

TETRAS operates asynchronously, allowing peptides to be synthesized simultaneously without waiting for others to complete. It assembles sequences from individual amino acids using automated SPPS, reducing manual effort and improving reproducibility.

Differentiated reaction vessels enable flexible scaling, while the completely modular design virtually eliminates downtime. TETRAS supports complex sequences, modifications, and secondary structures through a fully programmable platform.

Ideal for applications in chemistry, biochemistry, and molecular biology, TETRAS simplifies synthesis without compromising precision. Discover what’s possible with TETRAS

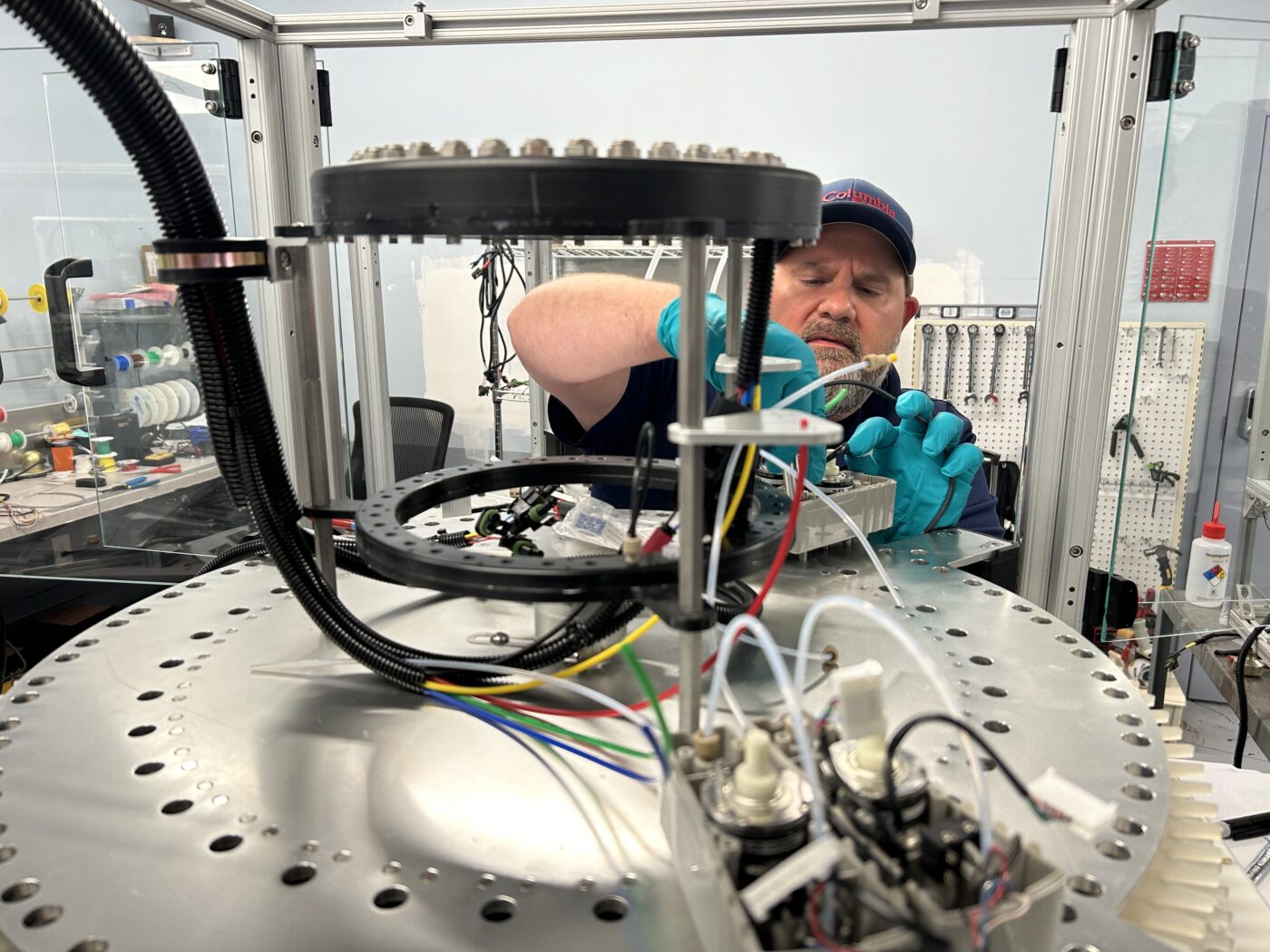

From the beginning, engineering has been the heart of everything we do. This mindset brought the first iteration of TETRAS to life. TETRAS and its systems were designed, built, and continually refined by the same dedicated team that remains with us today, ensuring unmatched expertise and innovation. Since its first iteration, TETRAS has evolved through rigorous testing and enhancements, while preserving core functions that have made it a trusted solution across diverse industries. Now available in three configurations—the TETRAS T⁴, TETRAS T⁸, and Refurbished TETRAS—it offers unparalleled flexibility. With the ability to synthesize up to 108 peptides simultaneously, TETRAS combines cutting-edge technology with proven reliability, all powered by our advanced SynClade software. Whether you’re just embarking on your journey into the world of peptide synthesis or you’re a seasoned expert, TETRAS is here to support and empower you every step of the way. With our innovative technology, proven reliability, and dedicated team, we’re committed to helping you achieve success in every synthesis. Welcome to TETRAS—where peptide innovation thrives.

For more information regarding peptide synthesization and ways in which you can improve your asynchronous peptide synthesizing processes, contact our team today. For corporate inquires contact Occam Design.

With 25 years of experience in medical device product development, Vas joined the TETRAS program in the development stage as Lead Engineer. He was tasked with addressing critical challenges faced by modern peptide synthesizers, such as cross-contamination, limited scalability, and downtime inefficiencies. A key focus was solving the inability to synthesize multiple peptides simultaneously—a need unmet by the numerous multiple-peptide synthesizers on the market, none of which operate asynchronously. By combining innovative engineering with practical design, Vas spearheaded the creation of TETRAS, the first asynchronous peptide synthesizer. Unlike traditional systems, TETRAS can run continuously, allowing chemists to add new reactions and remove completed reactors at any time. This breakthrough drastically enhances lab productivity while minimizing costly downtime. By solving these common issues, TETRAS quickly became the preferred choice for peptide chemists across four continents. For over a decade, it has remained at the forefront of peptide science. The rapid success of TETRAS led to the founding of our sister company, Occam Design, which now exclusively builds and services the TETRAS platform. Vas oversees the unified teams of Occam Design and TETRAS, where he has directed the development of over 20 medical devices. His expertise spans engineering, quality control, regulatory compliance, and production operations, ensuring that TETRAS remains a trusted name in peptide synthesis worldwide.

Jason joined the TETRAS project in its early days, working alongside Vas to shape its initial design, experimentation, and eventual implementation. His contributions to the original TETRAS platform laid the foundation for its continued success and evolution. Over the years, Jason has played a pivotal role in TETRAS R&D, including the creation of the TETRAS T⁸. His work has been a driving force behind the program’s research and development efforts. Today, Jason oversees R&D for the TETRAS program, ensuring the highest standards are maintained while also pushing the boundaries across our teams.

Joe joined the TETRAS team in 2013 as a part time engineer on the build team. While pursuing his degree, Joe played a vital role in every aspect of the TETRAS build process. As his experience and expertise grew with the expansion of the TETRAS program, Joe was promoted to TETRAS Team Lead in 2017. In his current role, Joe oversees the day-to-day operations of our R&D lab, managing the TETRAS build process, inventory, and service operations. He preforms every TETRAS installation and serves as the primary service contact for our partners, embodying our commitment to excellence and support.

Orion joined the TETRAS team in 2025 after working as a Quality Control Chemist in North Carolina. He brings valuable experience in chemical analytical instrumentation, including HPLC, LCMS, and ICP-MS, gained from his time in the pharmaceutical industry and as an undergraduate researcher. Orion assists the team through the build process while also playing a pivotal role in prototyping and testing various TETRAS R&D initiatives.

Every TETRAS model begins with the expertise of our dedicated build team. Under Joe’s supervision, the team guides each TETRAS model through our 12-week build process. Our team brings together diverse expertise in mechanical, electrical, and design engineering, ensuring precision at every step. By adhering to the finely tuned build protocols developed by Vas and Jason, we’re proud to deliver fast and efficient build timelines without compromising on quality.

With Occam Design and TETRAS operating under the same parent company, the ancillary work of the TETRAS program is managed by the Occam Team. This includes Business Development & Marketing, Talent Acquisition, and the accounting operations of the TETRAS program. Specific to TETRAS R&D, Occam Design provides a full suite of medical device development and manufacturing. The team of engineers play a critical role in the evolution of TETRAS. By having a multifaceted approach, we ensure the next step of TETRAS further emphasizes our commitment to empowering our users and the greater peptide community.

1201 East Oak St

Louisville KY 40204

Local: 1.502.714.7200

mpfeifer@occamdesign.com

© Occam Design, A Creosalus Company